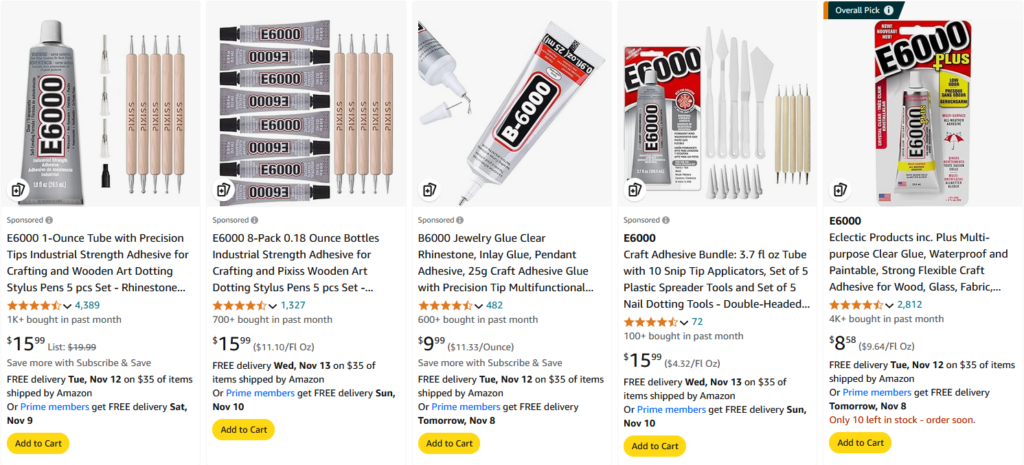

E6000 adhesive is a versatile, industrial-strength glue known for its exceptional bonding capability and flexibility. Crafted from an S-B-S co-block polymer and dissolved in strong solvents, E6000 is a popular choice for both DIY enthusiasts and professionals who need a reliable adhesive for various materials. Whether you’re repairing household items, crafting, or working on industrial projects, E6000 provides a durable and flexible bond that stands the test of time.

In this comprehensive review, we’ll dive into the characteristics that make E6000 unique, with a particular emphasis on the much-asked question: “How long does it take E6000 to dry?” We’ll also discuss the product’s composition, the best application practices, and factors influencing the drying process to ensure you achieve optimal results.

Table of Contents

E6000 Adhesive A Complete Guide to Drying Time

Key Features and Composition of E6000 Adhesive

E6000’s standout features come from its unique chemical structure. The adhesive uses a rubbery solid, S-B-S (styrene-butadiene-styrene) co-block polymer, which is dissolved in potent solvents. This chemical composition enables the glue to bond a wide range of materials, including:

- Wood

- Glass

- Ceramic

- Metal

- Fabric and leather

- Plastics

Its flexibility and adaptability to various materials have made it a preferred option across many industries. Unlike typical glues that can become brittle or crack over time, E6000 maintains its elasticity, which allows it to withstand pressure, impact, and environmental stressors. This feature is especially useful for applications that require a durable but slightly flexible bond, such as in jewelry-making, automotive repairs, and household fixes.

How Long Does It Take E6000 to Dry?

One of the top questions users have about E6000 is related to its drying and curing time. Understanding this process is crucial, as a proper cure ensures a strong, lasting bond. E6000 adhesive typically requires 24 hours to fully cure, though several factors can influence this timeline.

- Initial Tacky Time: Within minutes of application, E6000 becomes tacky, allowing you to position and adjust materials. This phase is critical for initial bonding.

- Bond Formation: A preliminary bond is often achieved within the first 30 minutes, especially if the materials are clamped or weighted.

- Full Cure: For maximum bond strength, it’s essential to allow E6000 to cure for 24 to 72 hours, depending on the material and environmental conditions.

Let’s look more closely at how these factors affect drying and curing time.

Factors Affecting the Drying and Curing Process

- Material Type and Porosity

Different materials have varying levels of porosity, which can significantly impact E6000’s drying time. Porous surfaces, like wood and fabric, allow the solvent in the adhesive to evaporate faster, speeding up the curing process. Non-porous surfaces, like glass and metal, on the other hand, restrict solvent evaporation, resulting in a longer cure time. - Temperature

Temperature plays a major role in the drying time of E6000. Warmer temperatures help the solvent molecules to evaporate more quickly, reducing the drying time. However, excessively high temperatures can soften the adhesive, weakening the bond. For best results, use E6000 in a well-ventilated area with a temperature between 70°F (21°C) and 85°F (29°C). - Humidity and Airflow

While humidity has a slight impact, airflow is more critical in aiding the drying process. Working in a room with good ventilation speeds up the evaporation of solvents in E6000, accelerating the cure. - Thickness of Application

The thickness of the E6000 layer also affects drying time. A thin layer dries much faster than a thick application, as there is less solvent to evaporate. When applying E6000 to materials like fabric or leather, a thin, even layer is often sufficient. However, for materials requiring a stronger bond, a thicker layer may be necessary, which requires more drying time.

Best Practices for Applying E6000 Adhesive

For optimal results with E6000 adhesive, it’s important to follow a few best practices that maximize bond strength and minimize drying time. Here’s a step-by-step guide:

- Prepare the Surfaces

Before applying E6000, ensure both surfaces are clean, dry, and free of dust, oil, or other contaminants. Cleaning with a mild solvent like rubbing alcohol can help prepare smooth surfaces like glass or metal. - Apply Evenly

Apply E6000 evenly to one or both surfaces, depending on the materials. Use a thin layer for faster drying, but ensure enough adhesive to achieve a strong bond. - Clamp or Weight

Clamping or weighting the materials can significantly enhance the bond strength. By applying consistent pressure, the adhesive spreads evenly across the bond area, reducing air gaps that might weaken the bond. - Allow Time for Initial Bond

Give E6000 a few minutes to form an initial tacky bond before adjusting or repositioning. This step helps secure the adhesive in place, minimizing slippage during the full cure process. - Wait for Full Cure

Patience is key when working with E6000. Allow the adhesive to cure undisturbed for at least 24 hours. For non-porous materials or thicker applications, a curing time of up to 72 hours is recommended for maximum bond strength.

Real-Life Applications and Use Cases for E6000 Adhesive

E6000’s versatility has earned it a devoted following across a wide range of applications. Here are some of the most common uses, each with specific considerations for drying and curing time:

- Jewelry Making

E6000 is a go-to adhesive in jewelry crafting due to its clear finish, flexibility, and strong bond. Whether attaching gemstones to metal settings or creating intricate beaded pieces, the quick tack time is a bonus. Jewelry makers often apply a thin layer to ensure minimal drying time, typically achieving a usable bond within 30 minutes to an hour, with a full cure in 24 hours. - Automotive Repairs

E6000’s resistance to vibration and impact makes it ideal for small automotive repairs, such as securing trim, emblems, or rubber seals. In automotive applications, where movement and environmental exposure are factors, it’s essential to allow the adhesive at least 48 to 72 hours to reach maximum durability. - Crafting and DIY Projects

From home decor projects to creating custom crafts, E6000’s flexibility and strength provide long-lasting results. For porous materials like wood or fabric, the adhesive cures relatively quickly, often reaching full strength in under 24 hours. For more intricate or larger projects, waiting the full 72-hour period ensures a strong bond that lasts. - Household Repairs

E6000 is popular for small household repairs, such as fixing broken ceramics, bonding plastic, or securing glass items. Non-porous surfaces, however, take longer to cure fully, so plan for at least 48 hours when using E6000 for household repairs involving glass or metal.

How E6000 Compares to Other Adhesives in Drying Time and Bond Strength

When considering the right adhesive for a project, E6000 stands out for its flexibility, durability, and unique curing process. Here’s a comparison with other adhesives to highlight E6000’s specific strengths:

- E6000 vs. Super Glue

Super Glue, or cyanoacrylate, dries almost instantly but can become brittle, especially on flexible or porous materials. While it’s suitable for quick fixes, Super Glue lacks E6000’s flexibility and durability, especially in applications that endure movement or temperature changes. However, for projects requiring a fast bond on small surfaces, Super Glue’s rapid drying time may be an advantage. - E6000 vs. Epoxy

Epoxy adhesives offer a very strong bond but usually require a mixing process and longer curing times, sometimes up to 24 hours or more. Epoxy is better suited for heavy-duty applications but lacks the versatility of E6000, which can be used on both rigid and flexible materials without mixing. E6000 also offers a clear finish, unlike many epoxy resins that dry with a slight yellow tint. - E6000 vs. Hot Glue

Hot glue offers an instant bond but is prone to softening under heat and doesn’t provide the same durability as E6000. For long-lasting projects, E6000’s bond strength and resistance to heat make it the better choice.

User Testimonials and Experiences with E6000 Drying Time

Many users of E6000 report positive experiences with its drying time and bond strength. Here are a few insights gathered from common reviews:

- Fast Initial Bond

Users often praise E6000’s ability to form a tacky bond within minutes. This initial tackiness is especially helpful for projects that need to be positioned and held in place without immediately clamping. Many crafters appreciate how quickly they can work with the adhesive, knowing they have some flexibility to adjust as they go. - Reliable Full Cure

Although the 24-hour full cure time may feel lengthy compared to some adhesives, users generally agree it’s worth the wait. After 24 to 72 hours, most report a solid, durable bond that withstands regular use, washing, or movement without weakening. - Slight Odor

One common observation is that E6000 has a strong odor due to the solvents in the formula. While this doesn’t affect drying time, many users recommend working in a well-ventilated area, especially for large projects, to minimize exposure to fumes.

Safety Tips and Handling Precautions for E6000 Adhesive

Because E6000 contains strong solvents, it’s essential to follow proper handling and safety guidelines:

- Work in a Well-Ventilated Area

The solvents in E6000 produce fumes that can be harmful if inhaled over extended periods. Always work in a space with adequate ventilation, such as a workshop or near an open window, to reduce inhalation of these fumes. - Avoid Direct Contact with Skin and Eyes

E6000 can cause skin irritation upon contact, so it’s recommended to wear gloves when applying the adhesive, especially for larger projects. In case of accidental contact with skin or eyes, rinse immediately with water and seek medical attention if irritation persists. - Store Properly

Store E6000 in a cool, dry place, tightly capped, to avoid evaporation and maintain its adhesive properties. Extreme heat can cause the glue to dry out in the tube or alter its bonding characteristics.

Final Thoughts on E6000 Adhesive: Durability and Drying Time

In conclusion, E6000 is a highly durable, flexible adhesive well-suited for a range of applications, from crafts to industrial repairs. Its unique formula allows for reliable bonding on both porous and non-porous surfaces, making it a versatile choice for various projects. While the typical drying time is 24 to 72 hours, its initial tack and gradual curing process offer flexibility and durability that surpass many other adhesives.

Ultimately, if you’re looking for an adhesive that combines strength with a flexible bond, E6000 is a solid choice. By understanding its drying time and following best practices for application, you can ensure a strong, lasting bond that’s resilient to the stresses of time, temperature, and movement.

Whether you’re a hobbyist crafter or a professional in need of an industrial-grade adhesive, E6000 stands out as a top performer in its category.

FAQs about E6000 adhesive

1. How long does it take for E6000 to dry and fully cure?

E6000 adhesive generally takes 24 hours to fully cure, though it may be ready for light handling within 30 minutes to 1 hour, depending on the application. For optimal results and maximum bond strength, allow it to cure for 24 to 72 hours. Drying time can vary based on factors such as the type of materials being bonded, the thickness of the adhesive layer, temperature, and humidity. For non-porous surfaces, like glass or metal, curing may take closer to the full 72 hours.

2. Can E6000 be used on fabric, leather, or clothing?

Yes, E6000 is suitable for use on fabric and leather. It forms a flexible and durable bond that works well with textiles, making it popular for crafts and fashion repairs. However, when used on fabric, apply a thin layer to avoid oversaturation, and let it cure for at least 24 hours. If using it on items that will be washed or exposed to moisture, ensure a full 72-hour cure time for the strongest bond. After curing, the adhesive remains flexible, which helps prevent cracking or breaking when the fabric moves.

3. Is E6000 waterproof once it dries?

Yes, E6000 is waterproof after it fully cures, making it ideal for applications that may be exposed to moisture, such as outdoor repairs or items used in wet environments. However, to ensure water resistance, it’s important to allow E6000 to cure completely. Once cured, it holds up well against water exposure and can even endure occasional washing. This makes it a popular choice for projects like jewelry-making and household repairs where water resistance is needed.

4. Can E6000 withstand high temperatures?

E6000 can withstand moderate temperatures but may start to soften if exposed to high heat for prolonged periods. It remains stable up to around 150°F (65°C). For applications in warm environments or on items exposed to sunlight, E6000 generally holds well, though extreme heat exposure (above 150°F) could affect the adhesive’s strength and flexibility. When applying it in warm conditions, avoid direct sunlight during curing, as excessive heat can impact the bond.

5. Is E6000 safe to use, and are there any precautions to take?

While E6000 is generally safe to use, it does contain strong solvents that produce fumes. To ensure safety, always use E6000 in a well-ventilated area, and avoid inhaling the fumes. Wearing gloves is recommended to prevent skin irritation, and if the adhesive comes into contact with your skin or eyes, rinse thoroughly with water. Additionally, store E6000 in a cool, dry place, away from children and pets, to prevent accidental exposure. Following these safety tips can help you use E6000 effectively and safely.